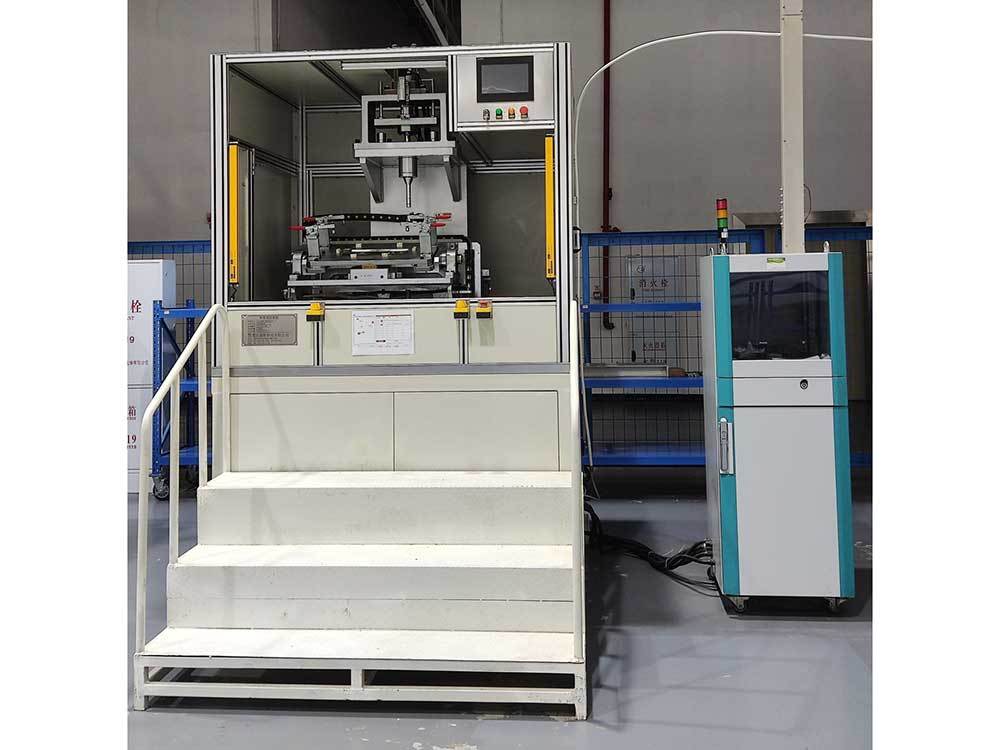

Combined press mounting equipment

Scope of application: mainly used for MIM shaping, motor press mounting, bearing, bushing, stator, rotor, differential, gear gearbox, auto parts and other process press mounting and shaping. The equipment control system is a servo electro-hydraulic system with low noise (40-50DB in standby mode, 60-70DB in normal operation) and energy saving (80% load, 1.2 kWh per hour). Siemens high-end PLC is used for logic control and data acquisition.

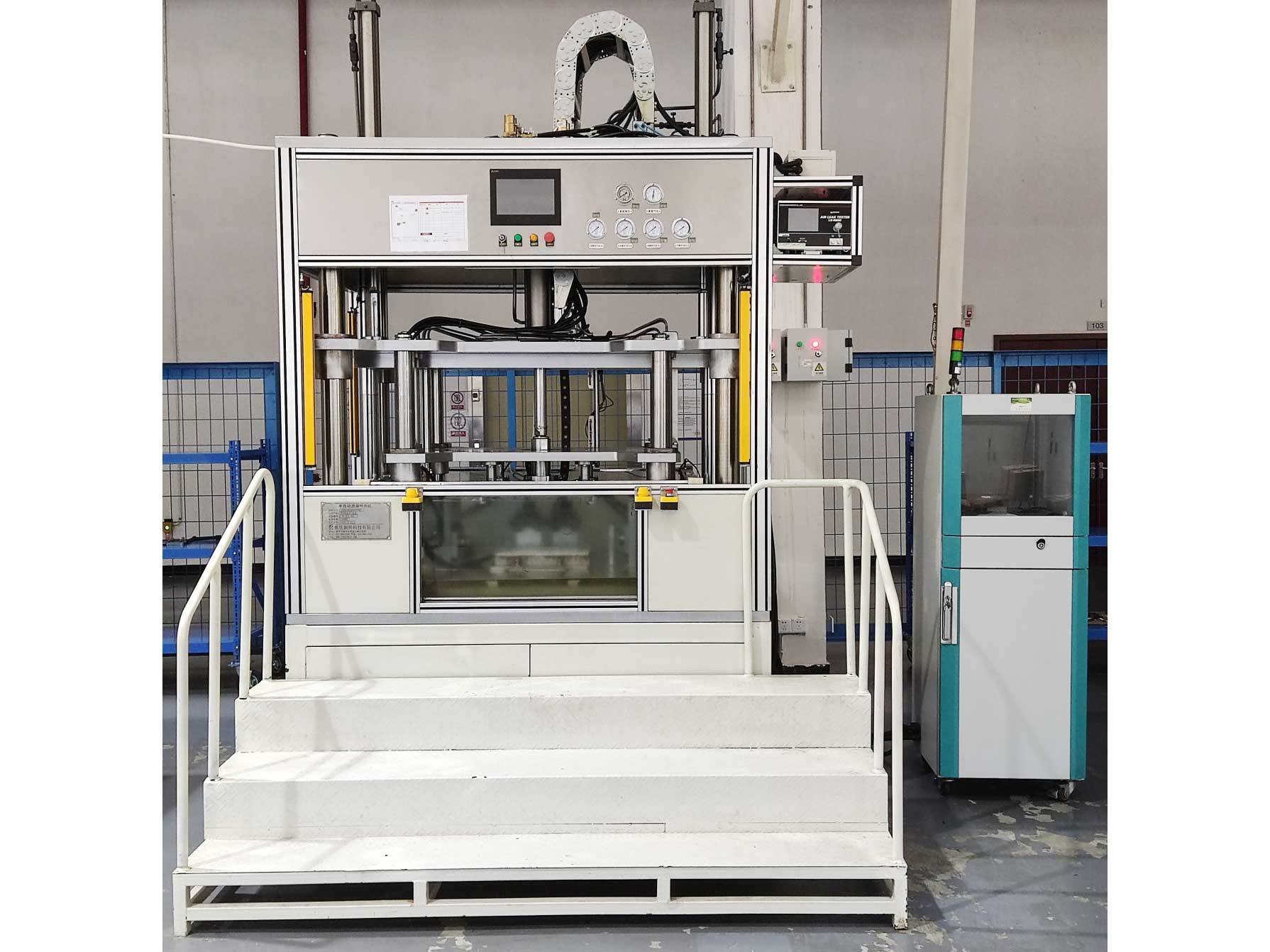

Seat ring conduit combination press

Press fitting of precision bearings, shaft sleeves, bushings, copper sleeves, auto parts, water pumps, turbochargers, gearboxes, gears, electric tools, auto chassis parts, rear axles, subframe bushings, gearboxes, gearboxes, differentials, stators, shafts, connectors and other products;

A press with a crank connecting rod as its working mechanism. Crank press is the most commonly used cold stamping equipment. It is simple in structure, convenient in use, stable in movement, and reliable in work. It is widely used in stamping, extrusion

Case cover bearing pressure loading machine

The bearing press fitting machine is a multi-functional small hydraulic machine tool. The table top has a U-shaped groove, which is convenient for the placement of the shaft and the pressing of the shaft parts. It is used for the press fitting of the shaft parts and the shaft sleeve parts, and can also complete the actions such as the stamping and the sleeve shape. Powder and plastic products that are not strictly pressed are mainly applicable to Xintaiming machine tools, electrical appliances, bearings, washing machines, automobile motors, motors and other industries, and to the assembly line of foreign-funded enterprises.

It is composed of cylinder sleeve and crankcase ventilation, and generally adopts high toughness gray cast iron CNC machine tool bed. It is the human body that supports the net weight of cylinder barrel, engine crankshaft tissue and any other parts and ensures the proper relative position between the parts. The cylinder is of cylinder barrel structure and installed in the cylinder barrel seat hole on the engine cylinder block to facilitate the repair or replacement of the damaged cylinder. Therefore, the structure is simple and the maintenance is convenient.

Right box damping sleeve press

It is composed of cylinder sleeve and crankcase ventilation, and generally adopts high toughness gray cast iron CNC machine tool bed. It is the human body that supports the net weight of cylinder barrel, engine crankshaft tissue and any other parts and ensures the proper relative position between the parts. The cylinder is of cylinder barrel structure and installed in the cylinder barrel seat hole on the engine cylinder block to facilitate the repair or replacement of the damaged cylinder. Therefore, the structure is simple and the maintenance is convenient.

Integrated dry and water inspection machine

The integrated water quality automatic monitoring station is a comprehensive online automatic detection system composed of conventional multi parameter online water quality analyzer, automatic measurement technology, automatic analysis technology, automatic control technology, computer application technology, communication network technology and other multidisciplinary modern technologies. The main function is to monitor the water quality change situation in real time, grasp the pollutant flux passing through the monitoring section qualitatively and quantitatively, and monitor the time variation law of pollutant concentration and flux in the section, so as to provide scientific basis for the pollution prevention and control of the basin and its supervision and management.

Special machine for crankshaft hole and camshaft hole of large diesel engine

The machining process of camshaft hole is divided into two processes: rough boring and fine boring. For the rough boring of camshaft holes of large and medium-sized engines, the special machine (or jig) for rough boring of shaft holes is generally used.

Water pump is a kind of machinery to transport liquid or pressurize liquid. It transmits the mechanical energy or other external energy of the prime mover to the liquid to increase the energy of the liquid. It is mainly used to transport liquid, including water, oil, acid-base liquid, emulsion, suspended lotion and liquid metal. It can also transport liquid, gas mixture and liquid containing suspended solids. Technical parameters of pump performance include flow, suction head, head, shaft power, water power, efficiency, etc; According to different working principles, it can be divided into volume pumps, vane pumps and other types. The positive displacement pump uses the change of the volume of its working chamber to transfer energy; Vane pump uses the interaction between rotating blades and water to transfer energy, including centrifugal pump, axial flow pump and mixed flow pump.

The precision servo press, referred to as servo press, CNC servo press, electronic intelligent servo press and other equipment, is a kind of precision ball screw driven by a servo motor to achieve closed-loop online control, so as to achieve precision pressure assembly.